How Is Moissanite Made: The Full Process Explained

At Revarado, we believe that brilliance should be as responsible as it is breathtaking. Lab-created moissanite has emerged as a popular high-tech gemstone, prized for its diamond-like sparkle and ethical appeal. But how exactly is moissanite made in the lab? In this in-depth post, we’ll explore the science of moissanite gemstone technology—covering the cutting-edge methods used to grow moissanite crystals, the raw materials and extreme conditions involved, and why Revarado’s commitment to quality and sustainability makes our pieces shine even brighter. Whether you’re choosing an engagement ring or adding a timeless staple to your jewelry collection, discover how is moissanite made from reactor to radiant gem reflects the innovative spirit at the heart of Revarado.

What Is Moissanite and Why Make It in a Lab?

Moissanite is a gem-quality form of silicon carbide (SiC), a compound of silicon and carbon. It was first discovered as tiny crystals in an Arizona meteor crater by Henri Moissan in 1893; however, natural moissanite is extremely rare. For practical use in jewelry, moissanite must be created in a laboratory. Scientists in the 1990s (notably at Cree Research in North Carolina) developed a process to grow large, pure SiC crystals, enabling Charles & Colvard to introduce moissanite gems to the market. Lab-created moissanite offers a brilliant, ethical alternative to diamond, with comparable hardness and even greater “fire” (colorful sparkle), at a fraction of the cost. It’s composed of common elements (Si and C) but requires extremely controlled conditions to form gem-quality crystals.

How Lab-Created Moissanite Is Made: Synthesis Methods

Growing moissanite crystals in the lab is a complex process that mimics or even exceeds the conditions of nature. All known methods involve combining silicon and carbon under extreme heat (and sometimes high pressure) to crystallize silicon carbide. The primary lab synthesis techniques include:

- Thermal Sublimation (Lely Process / Physical Vapor Transport) – the most common method

- Chemical Vapor Deposition (CVD) – a high-tech gas deposition method

- High-Pressure, High-Temperature (HPHT) Growth and Flux Growth – alternative techniques using molten solvents and/or intense pressure

Each method uses different machinery and process conditions. Still, all yield the silicon carbide boules (large single crystals) that are later cut into moissanite gemstones. We’ll break down each process:

How Is Moissanite Made With Thermal Sublimation (Lely Process / PVT Method)

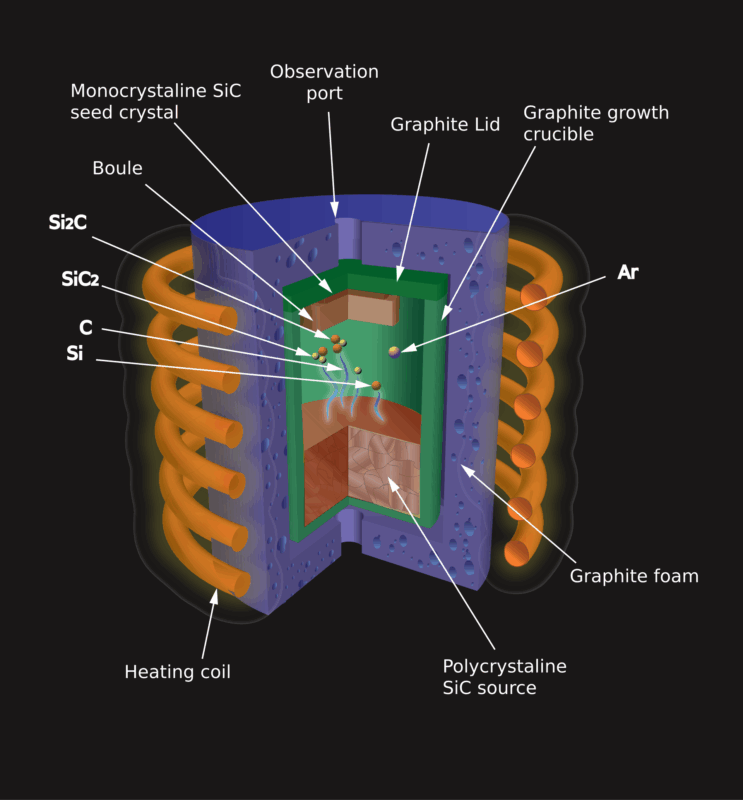

The Lely process, a form of Physical Vapor Transport (PVT), is the dominant technique (accounting for ~95% of SiC crystal production). It’s often referred to as a “thermal growing process” because it uses very high temperature to sublime and re-crystallize silicon carbide without needing extreme pressure. In this method, silicon carbide powder (the source material) is packed in a specialized graphite crucible along with a small seed crystal of SiC. The crucible is placed in an induction furnace and heated in an inert atmosphere (typically argon) to over 2,200 °C. At these temperatures, the SiC source material sublimates (transitions directly from solid to vapor). A slight temperature gradient in the furnace causes the vaporized species (Si, Si2C, SiC2, etc.) to migrate and condense onto the cooler seed, crystallizing a larger single crystal of moissanite. This is essentially how the original Lely process works, SiC vapor deposition onto a seed in a closed furnace.

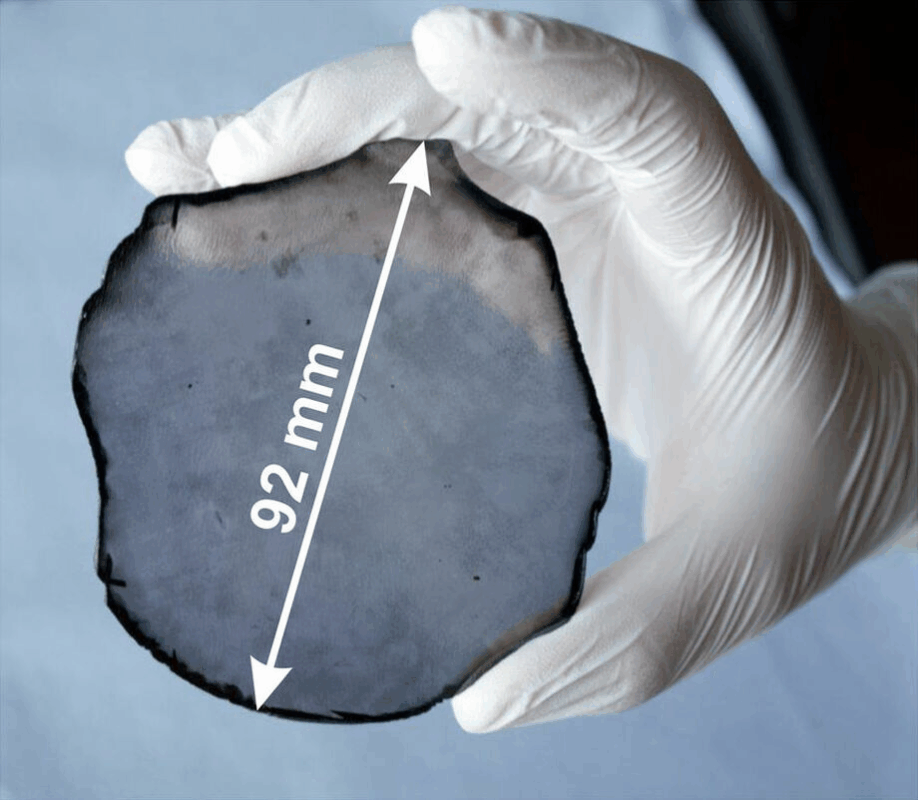

Because no liquid phase is involved, pressure can remain moderate (often near atmospheric), and the inert gas prevents oxidation. The growth is slow and careful: it typically takes several weeks to a few months to grow a sizable moissanite boule. For example, the American Gem Society notes that creating a single gem-quality moissanite can take 2–3 months. The resulting crystal (often slightly oblong or plate-like) is called a “boule.” Manufacturers like Charles & Colvard then slice and trim these boules into smaller rough pieces for faceting. The crystals are usually colorless or slightly tinted (yellow/green) as grown, depending on any doping; some boules appear yellow when hot and turn white upon cooling.

Raw materials & equipment: The thermal PVT method starts with high-purity SiC powder or a mix of elemental silicon and carbon. In fact, one way to obtain SiC source material is via the Acheson process (invented in 1891 for abrasives) – heating silica sand and coke in an electric furnace at ~2700 °C to produce crude SiC. For gemstone-grade growth, the powder is refined and packed in a graphite crucible inside an induction heating coil. The furnace is lined with thermal insulation and purged with inert gas. A polished seed of monocrystalline SiC (often 6H or 4H polytype) is mounted in the upper cooler region of the crucible. When the furnace runs at full temperature, the interior reaches (~2200–2400 °C) and the source powder sublimates. Over weeks, a single crystal SiC boule grows on the seed (often several mm to cm in diameter). This seeded sublimation approach yields high-purity moissanite crystals suitable for use in gemstones. Crucially, parameters such as temperature gradients, growth time, and controlled impurities (dopants) enable control over crystal quality and even color. Undoped SiC boules come out near-colorless, while adding tiny amounts of nitrogen or aluminum produces green, blue, or other fancy-colored moissanites.

Figure: In the popular Physical Vapor Transport method, silicon carbide (SiC) powder is heated in an inert gas furnace above ~2200 °C until it sublimates. The vapor travels to a slightly cooler seed crystal and condenses, growing a large single-crystal SiC boule (lab-created moissanite).

The thermal sublimation process (and its modern variants) is highly technical and energy-intensive, but it consistently produces the highest quality moissanite crystals. Over the years, engineers have improved it with designs like modified PVT and continuous-feed systems to enlarge boule size and reduce defects. Nonetheless, the fundamental idea remains heating SiC to vaporize and then re-solidify it as gem-grade crystal, a process that truly “grows” a gemstone from raw elements.

How Is Moissanite Made With Chemical Vapor Deposition (CVD) Method

Another method to create lab moissanite is Chemical Vapor Deposition (CVD), which is widely used to grow lab diamonds and advanced semiconductors. In CVD, gases containing silicon and carbon are introduced into a reactor chamber and broken down at high temperature, causing SiC to deposit layer-by-layer on a substrate. Essentially, this is a vapor chemistry approach rather than using solid powders.

In a typical SiC CVD process, a small seed crystal of moissanite (or sometimes a wafer of another material) is placed in a vacuum chamber. The chamber is heated (for SiC, often to 800–1500 °C range) and filled with a carbon-bearing gas (like methane or a hydrocarbon) and a silicon-bearing gas (such as silane, SiH4, or methylsilane). A plasma is generated (using microwave energy or RF heating) to crack the gas molecules. The freed silicon and carbon atoms then rain onto the seed surface in the form of silicon carbide, crystallizing atom by atom. By maintaining precise conditions (gas ratios, temperature ~1000°C, low chamber pressure ~0.01–0.1 atm), the SiC will continue to epitaxially grow on the seed, expanding the crystal layer by layer. Over days or weeks, this can produce a thicker SiC plate or block. High-temperature CVD has been used to grow electronic-grade SiC wafers, and in principle, it can produce gemstone-quality moissanite as well. CVD allows fine control of purity and doping (since gases can be introduced with dopant species for color or conductivity).

One challenge with CVD for moissanite is achieving significant thickness in reasonable time, it’s generally slower at building large volumes than the bulk sublimation method. However, CVD growth bypasses the need for extreme pressure and can yield very pure material. Some jewelry industry sources note that lab moissanite can be grown by CVD on a seed in a matter of weeks, though details often mirror the diamond CVD process. (It’s worth noting that a few references mistakenly describe moissanite CVD as if it were carbon-only deposition like diamond; in reality, a silicon source is required too.)

Raw materials & equipment: CVD uses industrial gases, e.g. methane (CH4) for carbon and silane (SiH4</sub}) or chlorosilanes for silicon. These flow into a CVD reactor, typically a vacuum chamber with controlled gas flow and heating. A plasma generator (microwave or RF) creates a glowing plasma that activates the gases. The equipment looks very different from an HPHT press or induction furnace; it resembles a high-tech oven with plasma inside. Conditions are lower pressure (near-vacuum) and moderately lower temperature than PVT. For instance, lab-grown diamond CVD runs at ~700–1200 °C; SiC may require the higher end of that range or above due to its higher stability. The growth rate might be on the order of a few microns per hour. Achieving gem-size crystals could take on the order of 1–2 months of continuous deposition, similar to other methods.

CVD-grown moissanite can be high purity and is typically single-crystalline if done on a proper seed. After growth, the plate or crystal would be removed, and any off-orientation material might be cut away. The remaining SiC crystal can then be sliced or cut into facetable pieces. CVD is not as widely used for moissanite as it is for lab diamonds, but it remains an essential technique in the toolkit of moissanite gemstone technology.

How Is Moissanite Made With High-Pressure High-Temperature (HPHT) and Flux Growth Methods

A third category of synthesis involves using molten fluxes and/or high pressures to grow moissanite crystals. These methods are conceptually similar to how lab-grown diamonds are made with HPHT, but they adapt the chemistry to silicon carbide. The idea is to dissolve the source materials in a solvent at high temperature and then crystallize SiC as the solution cools.

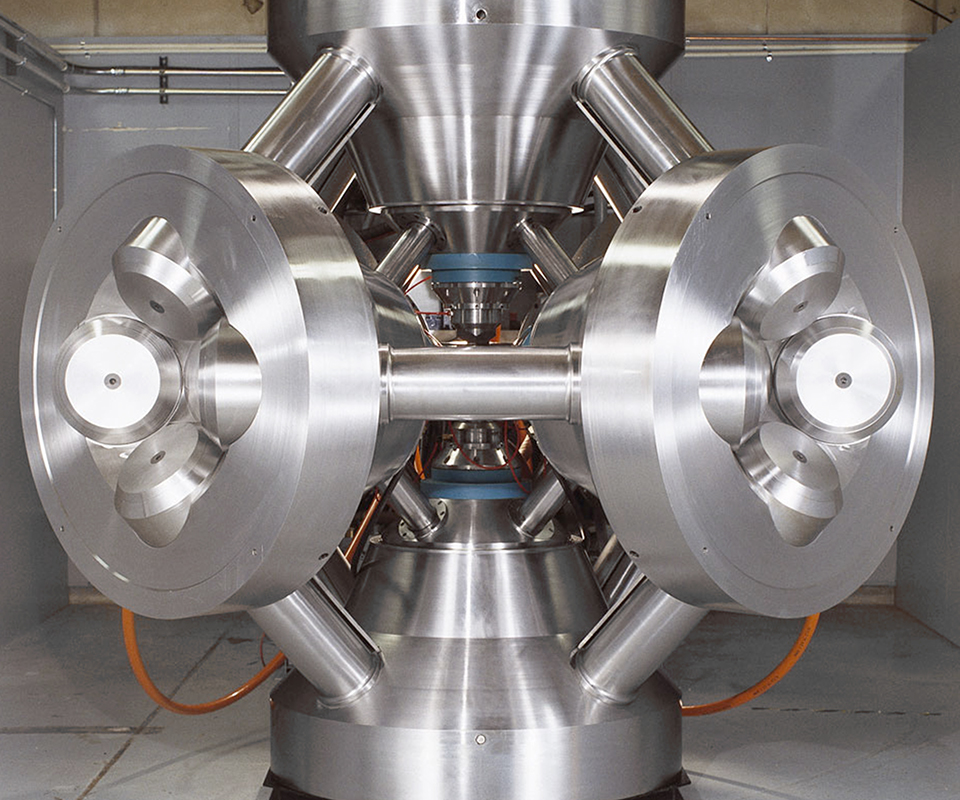

In one approach, silicon carbide powder is combined with a metal solvent (such as iron, nickel, or other catalysts) and loaded into a heavy HPHT press. Under extreme conditions, on the order of 1500 °C and 5–6 GPa pressure (tens of thousands of atmospheres, similar to the Earth’s mantle) the metal flux can dissolve the SiC and facilitate the growth of a crystal as the mixture slowly solidifies. This is analogous to HPHT diamond growth, where metal flux (like Fe-Ni) dissolves carbon and then precipitates diamond on a seed. In the case of moissanite, the presence of silicon changes the chemistry, but the principle is the same: extreme heat and pressure + a catalyst = crystal growth. One jewelry source describes this HPHT method for moissanite as “combining silicon carbide powder with a metal catalyst like iron or nickel, then subjecting it to extreme heat and pressure”. The outcome is a moissanite crystal that can be cut into gems. Because of the need for very high pressures, specialized equipment (multi-anvil presses or belt presses) is required, the machinery looks like a large steel apparatus with pistons (see image below). HPHT-grown moissanite is not as common as HPHT diamond, but it has been used, particularly by some manufacturers after Charles & Colvard’s patents expired.

High-Pressure High-Temperature (HPHT) apparatus used for lab gemstone synthesis. In HPHT growth, a capsule containing source materials is compressed to ~5–6 GPa and heated to ~1500 °C+, mimicking deep-earth conditions. This method can produce synthetic diamonds and, by using silicon/carbon plus a metal flux, synthetic moissanite crystals.

Another variant is flux growth at atmospheric pressure. Rather than enormous pressure, this uses a molten silicon-based flux in a furnace. For example, researchers in Japan developed a liquid-phase SiC growth technique: silicon and a solvent (plus carbon source) are melted in a crucible at ~2000 °C under inert gas (ambient pressure), and a seed crystal is pulled or held in the solution. As the melt cools very slowly, SiC crystallizes on the seed. This method is akin to how synthetic emerald or ruby can be grown from molten flux, but it’s challenging for SiC due to the high temperatures needed. Still, it shows promise for producing ultra-high-quality SiC with fewer crystal defects. Flux growth tends to be even slower, potentially several months for a crystal, and controlling the process is difficult, so it’s not yet widely used in moissanite gem production.

Raw materials & setup: Flux/HPHT methods start with either elemental silicon and carbon or pre-made SiC powder, plus a metal solvent (like transition metals or alloy). In HPHT, these go into a pressure capsule which is placed in the press and heated (often by a toroidal resistance heater) while pressure is applied by hydraulic rams. In flux growth at 1 atm, a graphite crucible holds the molten mixture; induction heating can melt the contents, and a seed crystal is introduced into the melt. Metals like iron, cobalt, or silicon alloys can act as flux to lower the effective crystallization temperature of SiC. As the solution saturates and cools, moissanite crystallizes out. Both techniques are essentially solution-growth methods (solidifying from a liquid), as opposed to the vapor-based PVT and CVD.

These alternative methods have been less publicized, but they are indeed “known methods” in lab-created moissanite production. Some Chinese manufacturers are believed to use proprietary flux growth processes to produce moissanite in various colors (by adding dopants in the melt). The HPHT route as described above also replicates the intense conditions of space or meteor impacts, one retailer notes that lab moissanite is made by “replicating the high-pressure and high-temperature conditions found in space” to form SiC crystals.

Process conditions: To summarize the typical conditions across methods:

- Thermal PVT: ~2100–2300 °C, ~1 atm inert gas, weeks to months of growth.

- CVD: ~1000–1500 °C, ~0.01 atm (vacuum), plasma assisted, moderate growth rate (microns/hour).

- HPHT: ~1300–1600 °C and ~5 GPa pressure (50,000+ atmospheres) in a press, using metal flux, growth in days to weeks.

- Flux (1 atm): ~1800–2000 °C in a molten bath, slow cooling over weeks/months.

Despite the different approaches, the end result is the same fundamental material: monocrystalline silicon carbide, ready to be fashioned into moissanite gems. After growth, the SiC boules or plates go through cooling and cutting. Typically, they are cored or sliced, then trimmed into rough preforms. These preforms are then sent for faceting and polishing, just like other gemstones. Skilled cutters shape each piece into the desired cut (round brilliant, oval, etc.), maximizing its brilliance. The finished moissanite gems are graded for quality and often laser-inscribed or certified by gemological labs.

Manufacturing Cost and Price

One of the biggest draws of lab-created moissanite is its affordability relative to diamond. Natural diamonds are expensive because of their controlled supply and mining costs; even lab-grown diamonds, while cheaper than natural, still cost a significant amount to produce (requiring either large HPHT presses or sophisticated CVD facilities running for weeks). In contrast, moissanite crystals, though difficult to grow, can be made in quantity and are not subject to the same market pressures as diamonds. As a result, a moissanite of a given size and quality typically retails for about one-tenth (or less) the price of an equivalent diamond. For example, a 1 carat round excellent-cut diamond might be several thousand dollars, while a 1 carat moissanite might be only a few hundred dollars. This value proposition is often cited by retailers: “moissanite offers a similar look to diamond at a fraction of the cost”.

Even when comparing to lab-grown diamonds, moissanite is usually much cheaper. The price of lab diamonds has been falling, but they are still 3–4 times the cost of moissanite per carat in many cases. Moissanite benefits from the use of relatively common raw materials (silicon and carbon are abundant) and potentially lower-energy processes than lab diamond. However, it’s worth noting that growing moissanite still requires significant investment (special furnaces or reactors, long growth cycles, etc.). When Charles & Colvard held the patent, they priced moissanite quite high initially. After the patent expired (2015), competition (especially from producers in China) drove prices down considerably. Today, moissanite is not much more expensive than cubic zirconia for the smallest sizes, and for larger sizes, it’s still dramatically cheaper than diamond. As one source put it, in the last decade moissanite has become “almost as affordable as CZ” while being far superior in quality.

Cubic zirconia, of course, is extremely inexpensive. It’s mass-produced by the ton using cheap raw materials (zirconium oxide powder) melted in bulk. A 1 carat CZ might cost only a few dollars (or less) wholesale. Typically, the cost of a CZ piece of jewelry is mostly the metal and labor, not the stone. CZ’s low cost makes it great for costume jewelry or temporary use, but it also signals its disposable nature, a CZ is not expected to last forever, and if it clouds or scratches, one can simply replace it. Moissanite occupies a middle ground: it’s not “cheap” in the sense of disposable, but it offers huge savings compared to diamonds. This accessible pricing allows consumers to get a large, high-quality gemstone without breaking the bank. Many buyers opt for a moissanite engagement ring, for instance, to maximize size or to save money for other priorities, while still getting a gorgeous sparkler.

From a manufacturing perspective, lab-grown diamonds still cost more to produce (the equipment and energy usage are high, and scaling up is challenging). Moissanite’s production, while complex, yields more output for the effort, multiple moissanite crystals can often be grown in a single furnace run, and they don’t require the costly post-growth HPHT treatments that some CVD diamonds need to improve color. Thus, moissanite will likely remain the more budget-friendly option among lab-grown gems.

Conclusion

Lab-created moissanite is a marvel of modern gem technology, born from science and grown in extreme lab conditions to yield a gemstone nearly as hard as diamond yet more fiery. We’ve seen that multiple high-tech methods (from the sublimation-based Lely process to advanced CVD and even HPHT techniques) can create moissanite crystals, using combinations of heat, pressure, and chemical reactions to coax silicon and carbon into glittering single crystals. The process may take months in a lab furnace or reactor, but the result is a stunning gemstone that offers durable beauty and brilliant optics.

When comparing moissanite vs. diamond vs. cubic zirconia, we find each has its place: Diamonds (whether mined or lab-grown) are prized for their heritage and singular refractive balance; moissanite stands out with superior fire, excellent durability, and a much lower price, making it an attractive choice for the practical romantics; cubic zirconia is the economical sparkler for short-term or low-cost needs, but it doesn’t match the lasting quality of the other two. Moissanite in particular strikes a compelling balance, it’s engineered luxury that aligns with both wallet and conscience.

For those interested in jewelry and science, moissanite represents how far materials technology has come. A gemstone that was first discovered in meteorites is now being grown in labs to light up jewelry showcases worldwide. Whether you’re drawn by the ethical aspect, the science, or simply the rainbow flashes of its sparkle, lab-created moissanite is a gemstone success story, proving that with ingenuity and engineering, Revarado can create brilliance rivaling nature’s best. It’s clear that moissanite has secured its spot in the jewelry world, not only as the ultimate diamond alternative but as a beautiful gem in its own right, the product of both cosmic mystery and human innovation.